|

|

|

| Home > Filters > Bandpass Filters > Interference Filters > 940nm Narrow Bandpass Filter, Interference Filter |

| |

|

| 940nm Narrow Bandpass Filter, Interference Filter |

.jpg)

|

|

Specifications:

|

Centre Wavelength(CWL):

|

940nm, +/-2nm

|

|

FWHM(50% point):

|

6nm, 10nm, 20nm, 30nm, 40nm, 60nm

|

|

Transmission:

|

Tave>85% @ 940nm

|

|

Size:

|

customized, from 2x2mm to Dia. 110mm, +/-0.1mm

|

|

Thickness:

|

0.3~3mm

|

|

Surface quality:

|

60/40~20/40

|

|

Clear aperture:

|

>90%, or full surface coatings

|

|

Substrate:

|

vary customized, such as B270, BK7, crystal, float or sodalime glass etc.

|

¡ñ specially designed for 940nm LED or Laser light source

¡ñ deeply block the other spectrum, no visible red light transmittance, which makes the LED light source completely invisible.

¡ñ Standard or customized features with different functions for the special applications

|

| |

|

|

|

940nm Narrow Bandpass Filter compatibly used with 940nm LED light or laser light source, which the image sensor only requires a small bandwidth of the 940nm NIR light to form the black and white image. Various applications or equipments require different bandwidth, from +/-5nm, +/-15nm to +/-30nm. LenOpTec develops a wide series of narrow bandpass filters for customers’ special applications, with different CWL and bandwidth. By our best cost-effective control, most customized filters can be fulfilled.

|

|

.jpg)

|

| |

|

|

| 940nm FWHM=60nm Interference Filter |

|

.jpg)

|

| |

|

|

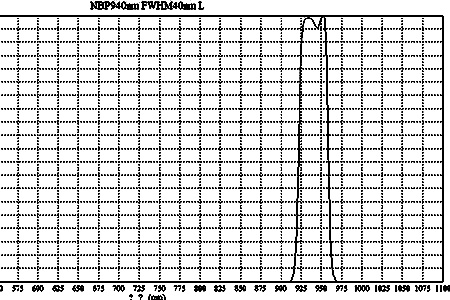

| 940nm FWHM=40nm Interference Filter |

|

|

|

Optical Filters are variously customized for some special applications, not only sizes, but also the bandwidth. Such as for most image forming systems, the transmission at CWL+/-5nm area shall be no less than 85%, to ensure a clear and bright enough image. A +/-5nm high transmission area is to allow the device reach a reasonable work temperature, such as -40~70¡æ, because the spectrum will drift to left about 3nm when temperature is higher, and to right when temperature is very low.

Most interference filters produced by Lenoptec are with the technical treatment of Ion Source Assistance Coating, to help the coatings reach a more tightness on the substrate, which can help the filters a long term steady operation.

|

|

|

| [ close ] |

|

|