|

|

Specifications:

|

Transmission:

|

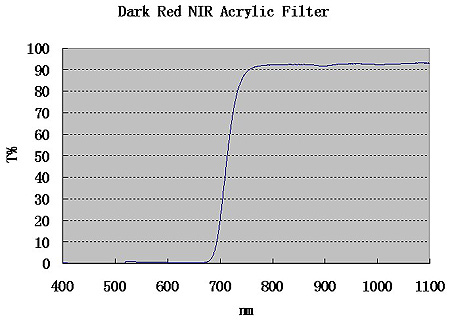

T>86% @ 780-1100nm, T=50% @ 720nm

|

|

Reflection:

|

Tave<=1% @ 400-700nm

|

|

Size:

|

Customized, any size and shapes

|

|

Thickness:

|

2~3mm

|

|

Surface quality:

|

80/50~60/40

|

|

Clear aperture:

|

Full clear or with protective bevel

|

|

Substrate:

|

Dark color Acrylics

|

¡ñ Acrylics, a kind of plastic made of PMMA

¡ñ Light weight, high NIR light transmission and deep visible light blocked

¡ñ commonly used inside the optical equipment to protect the surface. |

|

Acrylics made of PMMA, is a good material to be produced into optical filters, because of its good surface quality and high transmission in the spectrum of NIR light. Compared to glass filter, acrylics is much lighter, just a half weight as glass. And it is easier to be tooled into any shapes with much lower cost. NIR dark color acrylic filters absorb most visible light but only transmit NIR light after 720nm, so it is more and more commonly used for cost-effective systems, such as IR TV remote controller, video surveillance cameras, laser bar code scanner and other different NIR imaging optical systems. However, compared to glass filters, acrylics, as a kind of plastic, the surface quality will be easier to be scratched, so it is usually used inside the system to protection.

Notice items

- To temperature: the thin sheet will be intenerated above the 100 cent degrees, so it should not be used above the 85 cent degrees.

- To split: the surface hardness is similar to the aluminum. So we should pay attention to protect its surface when we are taking or putting. If you see the split on the sheet, please polish by the rubbing which is used in the yellow-aluminum to renew the excellent surface.

- To clean: it will appear the electric phenomena when you clean the surface by the dry cotton cloth. So it should be cleaned by the soft cotton cloth with 1% suds when you meet the dusty surface. For small pieces, it can be cleaned with alcohol.

To thermal expansion: the coefficient of liner thermal expansion is very big, flex strength is nine times of metal, we should think of the change of temperature when we are setting or fixing. |

|

|